Marine Oily Water Separator

[Search Related Products]

Marine Oily Water Separator

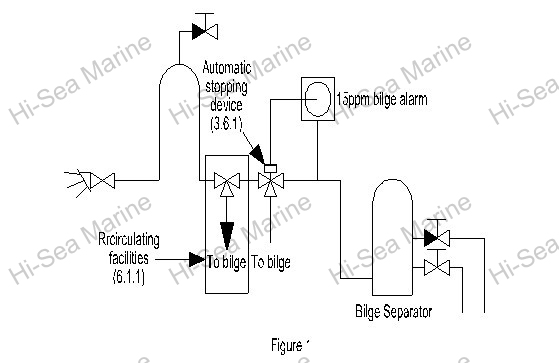

International Maritime Organization concerning the Marine Environment Protection Committee conferred upon it by international convention for the resolution IMO. MEPC. 107 (49) adopted on 18 July 2003. The resolution made the fully new requirement referring to 15ppm bilge treatment plant in Annex I of MARPOL73/78.

To comply with resolution IMO MEPC.107 (49), on board, especially ocean-going ships, they must be installed on board: 15ppm bilge separator, 15ppm bilge alarm and automatic stopping device.

Principle

The device adopts the combination of steam (electrical) heating. The1st stage cone plate gravity and coalesce separation; 2nd stage fiber filter and 3rd stage membrane permeation in order to make the treated bilge water to meet the requirements of discharge standard of the resolution of IMOMEPC.107 (49).

Troubleshooting:

|

No. |

Troubles |

Likely reasons |

Troubleshooting |

|

1 |

The vacuum inside the 1st coalescer is over -0.05Mpa |

The block of the Suck-in Pipes |

Clean the Suck-in Filter |

|

2 |

The loss of the vacuum of the 1st coalescer is over -0.01Mpa |

Out of Bilge Water |

Cease the device and start when water is there |

|

3 |

Frequent stop and start of the feeding pump |

Failure of the vacuum pressure protect |

Check the time delay relay in the electric control box |

|

4 |

The shock and noise of the feeding pump |

Out of water |

Pour into water or check whether Vs3 is opened |

|

Over pressure |

Check whether the pipes after the pump is unblocked |

||

|

5 |

The progress can¡¯t be operated as designed |

Failure of the Pneumatic Valve |

Check whether the on or off condition is normal, then check the electric control system. |

|

6 |

The bilge alarm can¡¯t control the solenoid valve |

Failure of the bilge alarm |

Check and repair the bilge alarm |

|

7 |

The pressure differences of the 1st and the 2nd stages is over 0.1Mpa |

The block of the 2nd stage filter core |

Replace it with a new one |

|

8 |

The 2nd pressure meter is over 0.2Mpa |

The discharge valve of the concentrated liquid is not opened |

Open it and adjust it |

|

The penetration rate of the membrane is too small |

Clean it or replace it |

||

|

9 |

The oil content of discharge water is always over board |

The separation rate gets lower |

Clean the device completely |

|

10 |

It can¡¯t discharge oil |

Be used for a long time of the liquid lever relay is destroyed |

If the liquid level relay works normally, take the level probe out and rub it bright |

|

11 |

The oil content meter is showed to ¡°EE¡± |

The glass tube is polluted or chapped |

If the glass tube is intact, please clean it with a brush |

|

12 |

The showed valve of oil content meter is changing all the time, and the valve fluctuation is big |

The air the device hasn¡¯t been emptied |

Wait for 10min, check whether the valve VS7 is opened, if VS7 is closed, please open it |

|

13 |

Feeding pump doesn¡¯t work |

The air is not enough |

Provide the compressed air with pressure of 0.4 Mpa |

|

Check whether the indicator lights of VS1 and VS2 on electric control box are lighting |

Check the switch of ¡¶water feeding, back flushing, oil discharge¡·is turned to manual position, if it is on manual position, it can operate after the indicator lights of VS1 and VS2 are went out. |

||

|

The pressure of vacuum pressure gauge is too high |

Check whether the valve VS7 is opened, if VS7 is closed, please open it |

||

|

JYB1£¬JYB3 level controllers are destroyed |

If they are destroyed, please replace them. |

||

|

14 |

The pneumatic valve can¡¯t be started up |

The solenoid valve has been destroyed, or the device hasn¡¯t been used for a long time |

Check the outlet of solenoid valve, if there is no air ejected, it is destroyed, please replace it. If the solenoid valve can work normally, provide compressed air of 0.8Mpa to open pneumatic valve, then resume normal pressure |

|

15 |

Safety valve jumps |

Outlet valve has not been opened,filter has been blocked |

Open outlet valve and replace fitter |

Technical Specifications

|

Model |

YWC- |

|||||||||

|

Technical Specifications |

0.25 |

0.5 |

1 |

1.5 |

2 |

2.5 |

3 |

4 |

5 |

|

|

Rated capacity(m3/h) |

0.25 |

0.5 |

1 |

1.5 |

2 |

2.5 |

3 |

4 |

5 |

|

|

Oil content of the discharged water |

¡Û15ppm |

|||||||||

|

Power of the electric heater£¨kw£© |

1kw |

3kw |

6 |

6 |

6 |

6 |

6 |

12 |

12 |

|

|

Electrical System |

AC 380V¡¢50Hz¡¢3¦Õ/ AC 415V¡¢50Hz¡¢3¦Õ/AC 440¡¢60Hz¡¢3¦Õ/AC 480V¡¢60HZ¡¢3¦Õ |

|||||||||

|

Power of the electric motor |

0.37kw |

0.55kw |

0.75kw |

1.1kw |

1.1kw |

1.5kw |

1.5kw |

2.2kw |

2.2kw |

|

|

Suction head |

¡Û6m-H2O |

|||||||||

|

Pressure of the discharged water |

5-10m-H2O |

|||||||||

|

Outline Dimension£¨L*W*H£©(cm) |

100*60 *125 |

110*69 *146 |

105*100 *162 |

110*113 *165 |

190*112 *170 |

190*112 *190 |

170*150 *190 |

228*170 *190 |

259*200 *190 |

|

|

Base |

5# |

6# |

6# |

6# |

8# |

8# |

8# |

10# |

10# |

|

|

Weight |

Dry Weight |

400 |

600 |

800 |

1060 |

1260 |

1500 |

1800 |

2100 |

2500 |

|

Wet Weight |

550 |

900 |

1200 |

1650 |

2260 |

2800 |

3200 |

3900 |

4600 |

|

Application