Marine Sewage Treatment Plant

[Search Related Products]

The Marine Sewage Treatment Plant belongs to the key devices for prevention of pollution form ships in seas and oceans according to the revised Annex IV of the International Convention of the Prevention of Pollution (MARPOL 73/78). The resolution MEPC. 2 (VI) adopted on 3 December 1976 is the present guidelines on implementation of effluent standards and performance tests for STP, which is called old standards. This device is according to the resolution MEPC. 159(55) enacted on 13 October 2006, which is called new standards. The convention (MARPOL 73/78) provides that all STPs installed on board on or after 1 January 2010 should meet the resolution MEPC159(55).

SWCM series: follow the IMO new standard MEPC159(55).

Principle Description:

This marine sewage treatment plant adopts the principle of Activated Sludge, Bio-contact Oxidation and Membrane Biological Reactor (MBR) to digest organic pollutant. MBR can treat organic pollutant efficiently, drastically and cleanly to insure the effluent can meet the requirements of the resolution MEPC. 159 (55) and other much harder requirements.

Advantages:

1. Adopting horizontal circular design, ellipse closures on both ends, pressure resistance and compact structure.

2. The device is adopted auto-control, and compliance with the requirement of 24-hours unattended cabin.

3. Adopting the 'MBR' technology, allow devices to narrow the size, and solve the conflict of small space of cabin, but big volume of device.

4. The intermittent aeration in bio-membrane tank and hollow fiber membrane tank, form the process of 'aerobic - anoxic', and resolve the problem of 'nitrogen and phosphorus removal'.

5. The device is adopting the principle of air-lifting to transfer the sludge from sediment tank and membrane tank to aeration tank, mealtimes the pump stops and air never stopped, so as the scale on the membrane surface comes down. Due to back flushing and clean the membrane online USD technology patent, so the life of membrane can be prolonged at least 8 to 9years.

6. 'On-line' cleaning technology, making the dirt on membrane off automatically, recover membrane flux. It can be solved the problem of opening the cleaning or replacement of membrane difficultly caused by the small space in cabin.

7. The effluent after further treatment can be reached at the requirement of water reuse.

For more information of the specification, please do not hesitate to contact us!

Technical Parameters:

|

Model |

SWCM- |

|||||||||||||||

|

15 |

20 |

25 |

30 |

40 |

50 |

60 |

80 |

100 |

120 |

150 |

200 |

250 |

300 |

400 |

||

|

Load |

Average load (L/d) |

1190 |

1540 |

1890 |

2310 |

3080 |

3780 |

4480 |

6020 |

7700 |

9100 |

11200 |

14700 |

18200 |

23100 |

30800 |

|

Peak load (L/h) |

149 |

193 |

237 |

289 |

385 |

473 |

560 |

753 |

963 |

1138 |

1400 |

1838 |

2275 |

2888 |

3850 |

|

|

Organic load (kgBOD5/d) |

0.595 |

0.77 |

0.945 |

1.155 |

1.54 |

1.89 |

2.24 |

3.01 |

3.85 |

4.55 |

5.6 |

7.35 |

9.1 |

11.55 |

15.4 |

|

|

Rated capacity (men) |

15 |

20 |

25 |

30 |

40 |

50 |

60 |

80 |

100 |

120 |

150 |

200 |

250 |

300 |

400 |

|

|

Max capacity(men) |

17 |

22 |

27 |

33 |

44 |

54 |

64 |

86 |

110 |

130 |

160 |

210 |

260 |

330 |

440 |

|

|

Electricity |

AC 380V/50Hz/3¦Õ, AC 415V/50Hz/3¦Õ, AC 440/60Hz/3¦Õ |

|||||||||||||||

|

Power (kW) |

2.5 |

2.5 |

2.5 |

2.5 |

3.0 |

3.0 |

3.5 |

4.0 |

4.0 |

4.0 |

6.0 |

6.0 |

7.0 |

9.0 |

11 |

|

|

External dimension (mm) L¡ÁW¡ÁH |

1870 ¡Á 1200 ¡Á 1400 |

1745 ¡Á 1400 ¡Á 1525 |

1935 ¡Á 1400 ¡Á 1560 |

1985 ¡Á 1500 ¡Á 1650 |

2400 ¡Á 1600 ¡Á 1700 |

2410 ¡Á 1700 ¡Á 1850 |

2670 ¡Á 1700 ¡Á 1850 |

2780 ¡Á 1900 ¡Á 2050 |

2795 ¡Á 2000 ¡Á 2200 |

3000 ¡Á 2000 ¡Á 2200 |

3050 ¡Á 2200 ¡Á 2300 |

3600 ¡Á 2200 ¡Á 2350 |

3880 ¡Á 2400 ¡Á 2570 |

4750 ¡Á 2400 ¡Á 2570 |

5950 ¡Á 2400 ¡Á 2570 |

|

|

Weight |

Dry weight(kg) |

1000 |

1000 |

1200 |

1200 |

1300 |

1450 |

1600 |

1850 |

2200 |

2300 |

2800 |

3000 |

3300 |

3700 |

4200 |

|

Wet weight(kg) |

2283 |

2640 |

2740 |

3500 |

4400 |

5073 |

5270 |

6517 |

8268 |

9166 |

11340 |

13267 |

16538 |

20357 |

25417 |

|

|

Effluent standard |

BOD5¡Ü25mg/L, COD¡Ü125mg/L, TSS¡Ü35mg/L, coliform¡Ü100/100ml, PH6~8.5, CL2¡Ü0.5mg/L |

|||||||||||||||

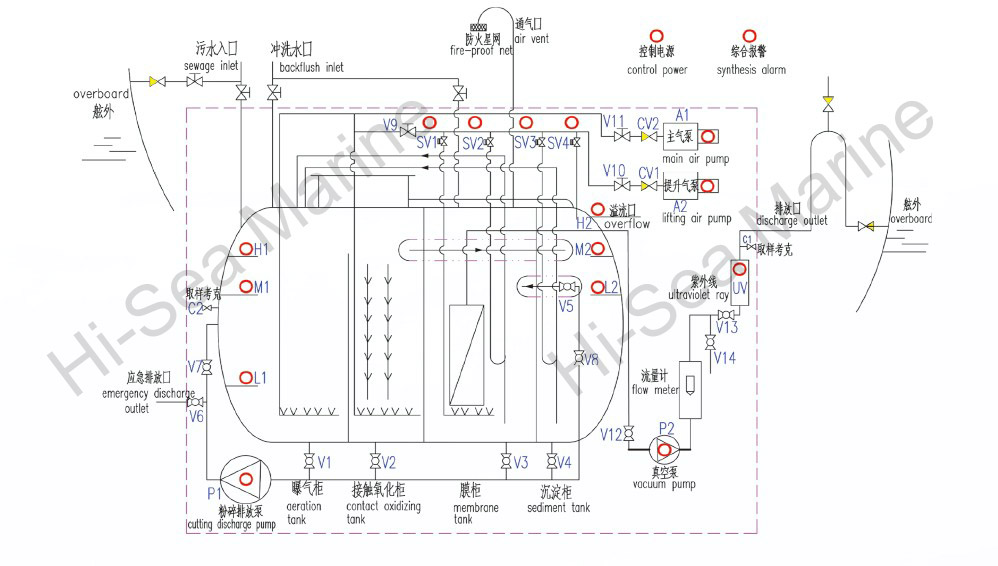

System Principle Drawing:

The Workshop and Storage:

The Certificates: