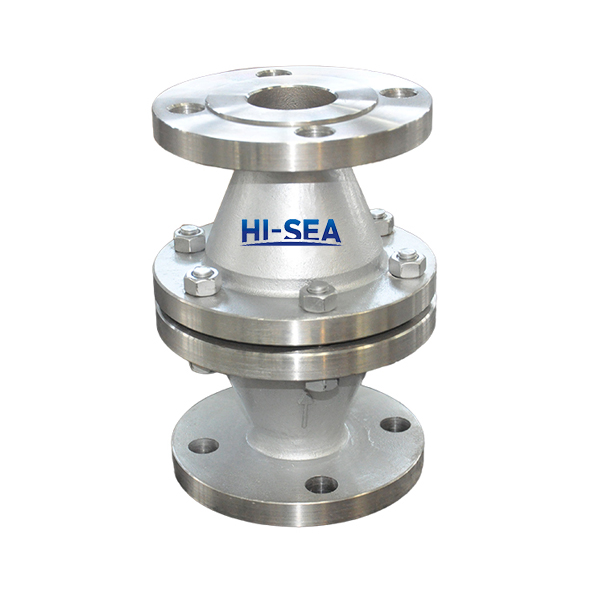

Marine Cast Steel Flame Arrestor

[Search Related Products]

Details

In order to ensure that the performance of the flame arrester reaches the purpose of use, before installing the flame arrester, you must carefully read the instructions provided by the manufacturer and carefully check whether the label is consistent with the requirements of the installed pipeline.

2. The flow direction mark on the flame arrester must be consistent with the flow direction of the medium.

3. It should be checked every six months. Check whether the fire retardant layer has defects such as blockage, deformation or corrosion.

4. The blocked fire retardant layer shall be cleaned to ensure that each hole is unblocked. The deformed or corroded fire retardant layer shall be replaced.

5. When cleaning the core of flame arrester, high-pressure steam, non corrosive solvent or compressed air shall be used for purging, and sharp hardware brushing is not allowed.

6. When reinstalling the fire retardant layer, the gasket shall be renewed and the sealing surface shall be confirmed to be clean and free from damage without air leakage.

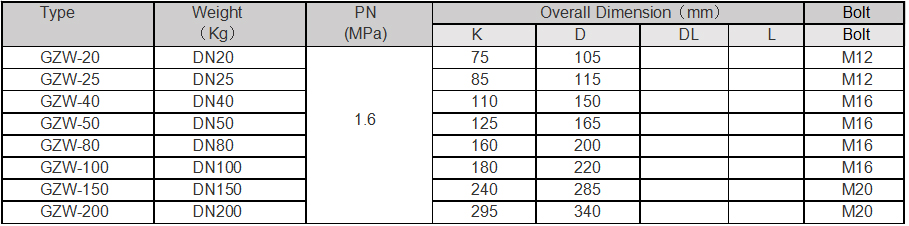

Specificatio

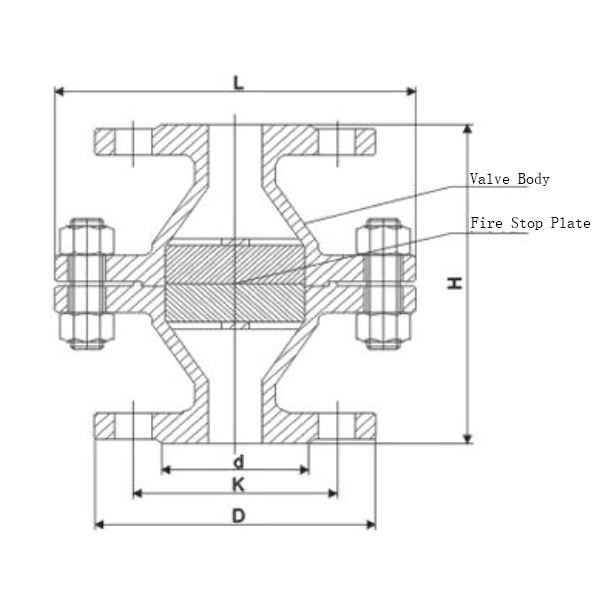

Drawing