CNC hose crimping machines

[Search Related Products]

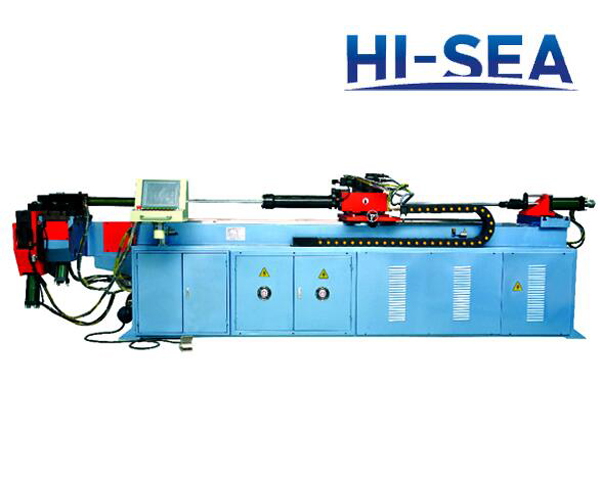

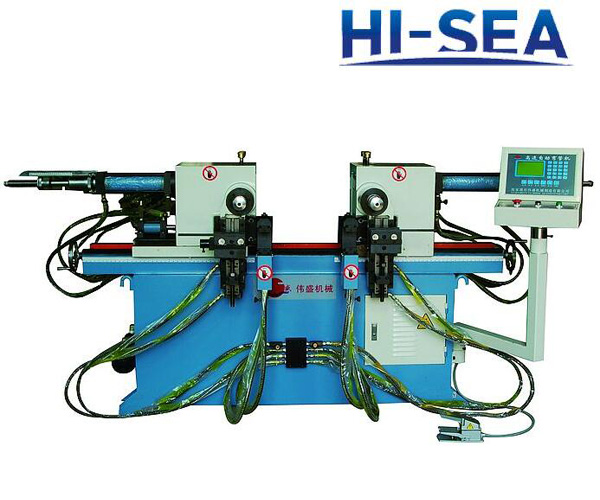

SK100 Numerical control pipe locking machines

Model SK-100 CNC Computerized Numerical Control hose crimpng machines newly innovated by our factory is suitable for hoping pipe processing of the assembly such as high pressure rubber tube, fiber pipe and plastic pipe used in industry, agriculture and fluid drive of engineering machinery. It has the advantages of wide hooping range, high precision (adopt PLC control), high degree automation, easy operation and maintenance, etc.

Technical Parameters

Crimping range: ¦Õ4-51mm

Industry tube inner diameter: MAX. 89mm

Crimping precision: 0.01mm

Power: 4KW

Voltage: 380V

maximum swage force: 252 tons

Rotated speed: 1440r/min

Oil pump displacement: 10ml/rad

Dimension: 858*910*1550mm

Weight: 800Kg

Maximum opening diameter: +68mm

Working principle

The oil pump driven by the electric motor outputs the hydraulic oil and push the piston in the hydraulic cylinder to make up and down reciprocating movement. Thus makes the two columns connecting with the piston drive the above board realizing up and down reciprocating movement, making the pressing block in the recess of the two up and down large square board push the die holder, and making the die holder to give rise to radial shrinkage. And in the end realize the hooping of the rubber tube by module. When the shrinkage reaches the set value on the control panel, the hooping will stop automatically. The change valve reverses automatically. The hydraulic oil enters into lower chamber of the hydraulic cylinder and drives the above board to move upward making the mould hole to enlarge. Then we can take down the hooped rubber tube assembly.

Working principle

The oil pump driven by the electric motor outputs the hydraulic oil and push the piston in the hydraulic cylinder to make up and down reciprocating movement. Thus makes the two columns connecting with the piston drive the above board realizing up and down reciprocating movement, making the pressing block in the recess of the two up and down large square board push the die holder, and making the die holder to give rise to radial shrinkage. And in the end realize the hooping of the rubber tube by module. When the shrinkage reaches the set value on the control panel, the hooping will stop automatically. The change valve reverses automatically. The hydraulic oil enters into lower chamber of the hydraulic cylinder and drives the above board to move upward making the mould hole to enlarge. Then we can take down the hooped rubber tube assembly.