AY Marine Single Two-stage Centrifugal Lubro-Pump

[Search Related Products]

Applications:

AY Type Single Two-stage Centrifugal Lubro-Pump , which is reformed and redesigned on the base of original Y type lubro-pump series. In order to meet the construction of the modernization adapt to the requirement of replacing the old with the new one soon which is focused on the sizing the energy, so we develop this new product, it has the following characteristics:

1. The original bearing body parts35, 50, 60 are replaced by bearing body45, 55, 70, in this way its reliability can be increased.

2. The hydraulic excess flow part adopt the hydraulic model of the high efficiency energy-saving Pump, in average, the efficiency is 5-8% higher than the old Y type lubro-pump.

3. In order to keep inheriting, the structure pattern, install size.

4. The lubro-pump pats have the strong all-purpose ability; its general-standard parts can be commonly used by several series.

5. The affiance of its selecting materials way and the principals part is mainly made of¢ò¡¢¢ókind material, the materials of some parts such as bearing body is up to two kinds, that is casting steel and casting iron, in this way, it makes very advantages for being used in the cold area, being used outdoor, it is a marine pump.

6. According to the different temperature, selecting hearing has three types that is air cooling, air fan cooling, water cooling, among them, air fan cooling is especially used for the area where the water resource is lack or the quality of water is worse.

¡ô Performance

Scope: flow capacity: Q=2.5-600m3/h lift H=30¡«330m Temperature T=-45¡æ¡«+420¡æ

AY type lubro-pump can be used in different field such as petroleum refining, petrochemical, chemical industry, the other field which transport the petroleum, liquid gas and the other medium which doesn't contain the particulate solids.

¡ô The pump¡¯s piping system

1. According to the temperature and the demand of application we use cooling-water to cool the shaft seal capacity, bearing or pump mounting the water amount for per pipe is 0.3-0.7m3/h,its pressure 0.2-0.3MPa¡£

2. Sealing flush is changing according to the different transporting medium and its temperature pressure or the other working condition, the seal liquid amount for per pump is as following table, both inter supply and outer supply is suitable for that.

The pressure of the seal liquid is usually higher than the pressure of the sealing capacity 0.07-0.1MPa£¬if the transporting medium is easily vaporizing, the hat pressure should be higher than the caponizing pressure 0.175-0.2MPa.

3. Steam line is equipped in case the transporting medium is easily precipitation crystal; its pressure should be 0.1MPa less or more.

|

Sealing nominal diameter£¨mm£© |

13-47 |

48-59 |

60-84 |

85-95 |

96-133 |

|

Average seal liquid amount£¨m3/h£© |

0.18 |

0.24 |

0.36 |

0.48 |

0.66 |

Performance Parameter

| Type |

Capacity (m3/h) |

Head (m) |

Speed (r/min) |

Efficient (%) |

Cavitation superfludity (m) |

Shaft power (kw) |

Motor Model | Motor Power (kw) | Pump weight (kg) |

| 40AY40¡Á2 | 6.25 | 80 | 2950 | 30 | 2.7 | 4.5 | YB132S2-2 | 7.5 | 165 |

| 40AY40¡Á2A | 5.85 | 70 | 2950 | 30 | 2.6 | 3.7 | YB132S2-2 | 5.5 | 165 |

| 40AY40¡Á2B | 5.4 | 60 | 2950 | 30 | 2.5 | 2.9 | YB112M-2 | 4 | 165 |

| 40AY40¡Á2C | 4.9 | 50 | 2950 | 30 | 2.5 | 2.2 | YB100L-2 | 3 | 165 |

| 50AY60 | 12.5 | 67 | 2950 | 42 | 2.9 | 5.4 | YB132S2-2 | 7.5 | 110 |

| 50AY60A | 11 | 53 | 2950 | 39 | 2.9 | 4.1 | YB132S2-2 | 5.5 | 110 |

| 50AY60B | 10 | 40 | 2950 | 37 | 2.8 | 2.9 | YB112M-2 | 4 | 110 |

| 50AY60¡Á2 | 12.5 | 120 | 2950 | 35 | 2.8 | 11.7 | YB160L-2 | 18.5 | 170 |

| 50AY60¡Á2A | 12 | 105 | 2950 | 35 | 2.4 | 9.8 | YB160M2-2 | 15 | 170 |

| 50AY60¡Á2B | 11.5 | 89 | 2950 | 33 | 2.3 | 8.4 | YB160M2-2 | 11 | 170 |

| 50AY60¡Á2C | 11 | 78 | 2950 | 33 | 2.2 | 7.1 | YB160M2-2 | 11 | 170 |

| 65AY60 | 25 | 60 | 2950 | 52 | 3 | 7.9 | YB160M2-2 | 11 | 150 |

| 65AY60A | 22.5 | 49 | 2950 | 51 | 3 | 5.9 | YB132S2-2 | 7.5 | 150 |

| 65AY60B | 20 | 38 | 2950 | 49 | 2.7 | 4.2 | YB132S2-2 | 5.5 | 150 |

| 65AY100 | 25 | 110 | 2950 | 47 | 3.2 | 15.9 | YB180M-2 | 22 | 180 |

| 65AY100A | 23 | 92 | 2950 | 46 | 3.1 | 12.5 | YB160L-2 | 18.5 | 180 |

| 65AY100B | 21 | 73 | 2950 | 45 | 3 | 9.3 | YB160M2-2 | 15 | 180 |

| 65AY100¡Á2 | 25 | 200 | 2950 | 47 | 2.8 | 29 | YB200L2-2 | 37 | 280 |

| 65AY100¡Á2A | 23 | 180 | 2950 | 46 | 2.8 | 24.5 | YB200L2-2 | 37 | 280 |

| 65AY100¡Á2B | 21.5 | 155 | 2950 | 45 | 2.7 | 20.2 | YB200L2-2 | 30 | 280 |

| 65AY100¡Á2C | 19.5 | 130 | 2950 | 44 | 2.7 | 15.7 | YB180M-2 | 22 | 280 |

| 80AY60 | 50 | 60 | 2950 | 62 | 3.2 | 13.2 | YB160L-2 | 18.5 | 160 |

| 80AY60A | 45 | 49 | 2950 | 61 | 3.2 | 9.8 | YB160M2-2 | 15 | 160 |

| 80AY60B | 40 | 39 | 2950 | 60 | 3.1 | 7.1 | YB160M2-2 | 11 | 160 |

| 80AY100 | 50 | 100 | 2950 | 56 | 3.1 | 24.3 | YB200L2-2 | 37 | 200 |

| 80AY100A | 45 | 85 | 2950 | 55 | 3.1 | 18.9 | YB200L2-2 | 30 | 200 |

| 80AY100B | 41 | 73 | 2950 | 54 | 2.9 | 15.1 | YB180M-2 | 22 | 200 |

| 80AY100¡Á2 | 50 | 200 | 2950 | 57 | 3.6 | 47.8 | YB280S-2 | 75 | 350 |

| 80AY100¡Á2A | 46 | 175 | 2950 | 55 | 3.5 | 39.9 | YB250M-2 | 55 | 350 |

| 80AY100¡Á2B | 43 | 150 | 2950 | 54 | 3.3 | 32.5 | YB225M-2 | 45 | 350 |

| 80AY100¡Á2C | 40 | 125 | 2950 | 52 | 3.3 | 26.2 | YB200L2-2 | 37 | 350 |

| 100AY60 | 100 | 60 | 2950 | 70 | 4.1 | 23.3 | YB200L2-2 | 30 | 170 |

| 100AY60A | 90 | 49 | 2950 | 61 | 4.5 | 18.8 | YB200L2-2 | 30 | 170 |

| 100AY60B | 79 | 38 | 2950 | 65 | 3.5 | 12.6 | YB160L-2 | 18.5 | 170 |

| 100AY120 | 100 | 120 | 2950 | 63 | 4.3 | 51.9 | YB280S-2 | 75 | 285 |

| 100AY120A | 93 | 105 | 2950 | 61 | 4 | 43.6 | YB250M-2 | 55 | 285 |

| 100AY120B | 85 | 88 | 2950 | 59 | 3.8 | 34.5 | YB225M-2 | 45 | 285 |

| 100AY120C | 78 | 75 | 2950 | 56 | 3.6 | 28.5 | YB200L2-2 | 37 | 285 |

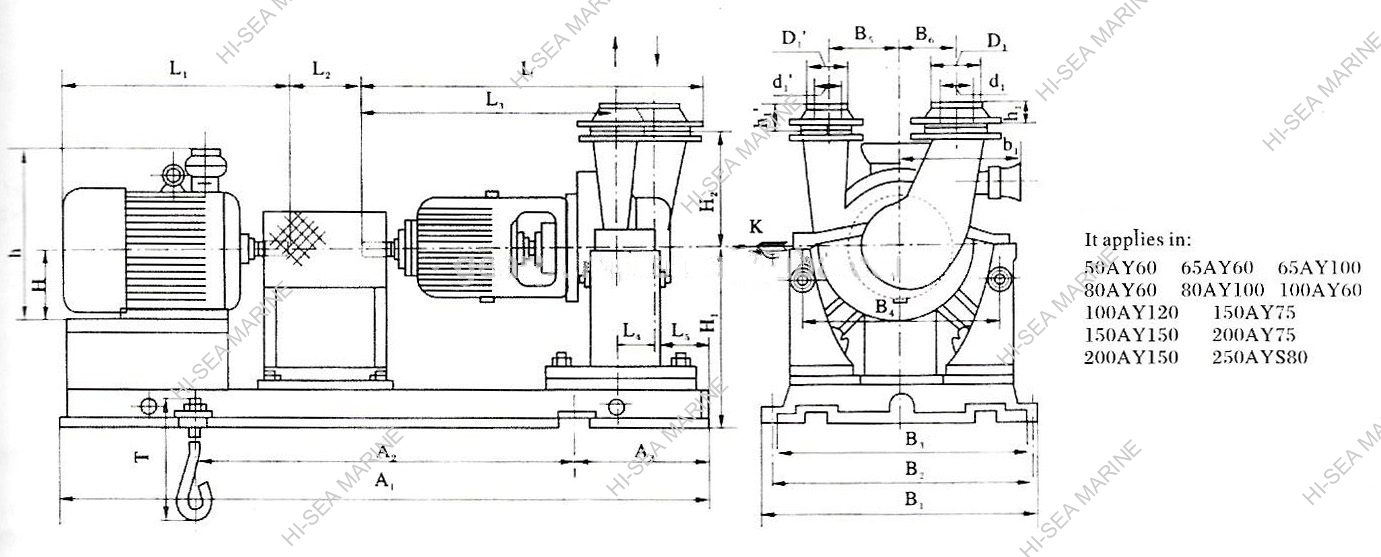

Structure:

Our Certifications: