3G Marine Three Screw Pump

[Search Related Products]

Applications:

1. 3G three screw pump high pressure oil pump is a kind of positive displacement rotary pump with the properly meshing in pump block.

2. It could be used to transfer non-corrosive oil or lubricated liquid that similar to oil, and the double jacket one could pump heavy oil, bitumn, resin.

3. Pump is with double jacket casing which can be heated by hot steam, thermal oil, etc to reduce the viscosity of fluids with easy solidification.

4. Widely used in oil and gas field, shipbuilding, petrochemical industry, thermal power plant, etc.

¡ô Feature

1. Medium is delivered in axial direction continuously without agitation and pulsation.

2. Small vibration and low noise .

3. High pressure and high efficiency .

4. Simple structure, easy disassembly and assembly .

5. Small volume and light weight.

6. Slight wear and long life of the pump.

¡ôMaterial: The driving and driven screw 16MnCrS5,40Cr,45,38CrMoALA¡¡Pump casing:¡¡HT200,QT450-10,ZCuSn10Pl,ZG270-500.

¡ô According to the application modes three screw pump is divided into five series:

|

Series |

Main application |

Performance scope |

|

|

Capacity (m3/h) |

Pressure (MPa) |

||

|

3G |

Lub oil visc3-20oE;temp¡Ü80¡æ |

0.6-570 |

2.5 |

|

3GR |

Heavy fuel oil visc3-50oE;temp¡Ü120¡æ |

0.6-570 |

2.5 |

|

3GR |

Light fuel oil visc1.2-5oE;temp¡Ü120¡æ |

0.6-570 |

1.6 |

|

3GW |

High temp fuel heated oil;temp¡Ü150¡æ |

0.6-363 |

1.6 |

|

3GN |

High visc oil 100oE;temp¡Ü80¡æ |

0.6-636 |

2.5 |

Model Explanation

for example 3G25¡Á4-46

3G: three screw pump

25: out-side dizmeter of the driving screw 25mm

4: potch number of the screw

46: 46¡ã pitch angle of the screw

R: heavy fuel oil

r: light fuel oil

W: high temperature heated oil

N: high visc oil

A: code of design improvement

S: double suction

Performance Parameter

|

Model |

Pressure |

Capacity |

Speed |

NPSH (m) |

Efficiency |

Motor |

||

|

m3/h |

L/min |

Power (kw) |

Model |

|||||

|

25¡Á4-46 |

1.0 |

0.8 |

13 |

1450 |

4 |

62 |

0.75 |

Y802-4 |

|

2.5 |

0.6 |

10 |

60.6 |

1.5 |

Y90L-4 |

|||

|

1.0 |

2.0 |

33 |

2900 |

4.5 |

59.4 |

1.5 |

Y90S-2 |

|

|

2.5 |

1.6 |

26 |

69 |

3 |

Y100L-2 |

|||

|

30¡Á4-46 |

1.0 |

1.6 |

26 |

1450 |

4.5 |

63.5 |

1.1 |

Y90S-4 |

|

2.5 |

1.2 |

20 |

61 |

2.2 |

Y100L1-4 |

|||

|

1.0 |

3.6 |

60 |

2900 |

5 |

60 |

2.2 |

Y90L-2 |

|

|

2.5 |

3.2 |

53 |

69 |

4 |

Y112M-2 |

|||

|

36¡Á4-46 |

1.0 |

2.8 |

46 |

1450 |

4.5 |

66 |

2.2 |

Y100L1-4 |

|

2.5 |

2.4 |

40 |

66.5 |

4 |

Y112M-4 |

|||

|

1.0 |

6.5 |

108 |

2900 |

5 |

60.5 |

4 |

Y112M-2 |

|

|

2.5 |

6 |

100 |

72 |

7.5 |

Y132S2-2 |

|||

|

42¡Á4-46 |

1.0 |

4.8 |

80 |

1450 |

5 |

62 |

4 |

Y112M-4 |

|

2.5 |

4.2 |

70 |

73 |

5.5 |

Y132S1-4 |

|||

|

1.0 |

10.5 |

175 |

2900 |

5.5 |

61 |

5.5 |

Y132S1-2 |

|

|

2.5 |

10 |

166 |

72 |

15 |

Y160M2-2 |

|||

|

45¡Á4-46 |

1.0 |

6.3 |

106 |

1450 |

5 |

70 |

3 |

Y100L2-4 |

|

2.5 |

5.9 |

99 |

74 |

7.5 |

Y132M-4 |

|||

|

1.0 |

13.5 |

225 |

2900 |

5.5 |

60 |

7.5 |

Y132S2-2 |

|

|

2.5 |

13 |

217 |

75 |

15 |

Y160M2-2 |

|||

|

60¡Á4-46 |

1.0 |

15.5 |

255 |

1450 |

5 |

71.3 |

11 |

Y160M-4 |

|

2.5 |

14.5 |

245 |

74 |

15 |

Y160L-4 |

|||

|

1.0 |

32 |

533 |

2900 |

5.5 |

63 |

18.5 |

Y160L-2 |

|

|

2.5 |

31.5 |

525 |

77 |

37 |

Y200L2-2 |

|||

|

70¡Á2-46 |

0.6 |

24 |

400 |

1450 |

5 |

71 |

7.5 |

Y132M-4 |

|

1.0 |

23.5 |

390 |

75 |

11 |

Y160M-4 |

|||

|

1.6 |

22.5 |

370 |

76 |

15 |

Y160L-4 |

|||

|

70¡Á4-46 |

1.0 |

24.5 |

408 |

1450 |

5 |

72.5 |

18.5 |

Y180M-4 |

|

2.5 |

23.5 |

392 |

79 |

30 |

Y200L-4 |

|||

|

80¡Á2-46 |

0.6 |

36.5 |

608 |

1450 |

5 |

72 |

11 |

Y160M-4 |

|

1.0 |

35 |

594 |

75.5 |

18.5 |

Y180M-4 |

|||

|

1.6 |

34.5 |

575 |

76.5 |

22 |

Y180L-4 |

|||

|

80¡Á4-46 |

1.0 |

37 |

617 |

1450 |

5.5 |

72 |

30 |

Y200L-4 |

|

2.5 |

35 |

590 |

78.1 |

45 |

Y225M-4 |

|||

|

100¡Á2-46 |

0.6 |

72.5 |

1208 |

1450 |

5 |

73 |

22 |

Y180L-4 |

|

1.0 |

71 |

1183 |

77 |

37 |

Y225S-4 |

|||

|

1.6 |

60.5 |

1158 |

79 |

45 |

Y225M-4 |

|||

|

100¡Á4-46 |

1.0 |

72.5 |

1208 |

1450 |

5.5 |

73 |

55 |

Y250M-4 |

|

2.5 |

70 |

1165 |

78.5 |

75 |

Y280S-4 |

|||

|

S100¡Á3-27 |

0.6 |

72 |

1196 |

1450 |

6 |

62 |

22 |

Y180L-4 |

|

1.6 |

70 |

1160 |

72 |

55 |

Y250M-4 |

|||

|

2.5 |

69 |

1145 |

74 |

75 |

Y280S-4 |

|||

|

S120¡Á3-27 |

0.8 |

123 |

2055 |

1450 |

6 |

74.5 |

55 |

Y250M-4 |

|

1.5 |

120 |

2010 |

76 |

90 |

Y280M-4 |

|||

|

2.5 |

115 |

1920 |

78.5 |

132 |

Y315M-4 |

|||

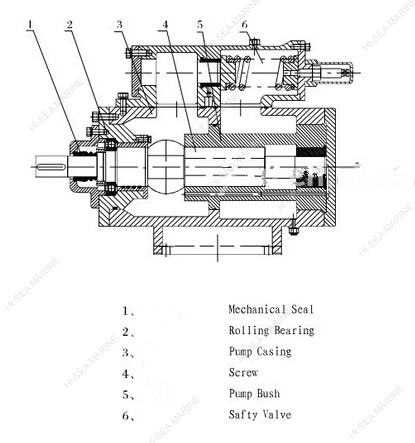

Structure

Photo

Our Certification